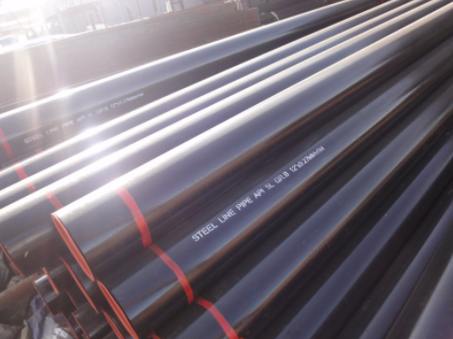

Carbon steel pipe is a durable material made from carbon steel, which is an alloy of iron and carbon. Due to its strength and ability to withstand stress, carbon steel pipes are used in a variety of heavy industries such as infrastructure, ships, stills and fertiliser equipment. UNITED manufactures two types of carbon steel pipes: seamless pipes and welded pipes, and we give you an overview of the differences between them.

Stainless steel welded tubes are made by joining opposing edges of flat iron bars together. The metal is subjected to very high heat to make it ductile. The tube is then passed through a recess and a rolling mill. The thin iron sheet is heated and passed through a tapered opening, forcing its edges to curl and form the tube. The edges are then folded and welded together to complete the tubes.

Seamless stainless steel pipes do not have welded seams. In order to manufacture seamless stainless steel pipes, ingots or billets are used as the raw material. Ingots are a large rectangular or square cross-section. They have a high degree of ductility and flexibility. The solid billet is heated and melted into a cylindrical shape and then rolled until it is stretched and hollow. A hole is drilled in the centre of the solid cylinder to make a seamless tube. These tubes are thin walled, light weight and strong.

1. Length

Seamless steel tubes are relatively short in length, whereas welded tubes can be manufactured in long continuous lengths.

2. Appearance differences

Seamless steel pipes are made from billets. Defects on the outer surface of the billet cannot be eliminated by the hot rolling process and can only be polished after the product is finished. In the wall reduction process, defects can only be partially eliminated. The surface quality of welded steel pipe is much better than that of seamless steel pipe.

3. Cost and price

Usually the cost of seamless steel pipe is higher than welded steel pipe because of raw materials, manufacturing equipment and processes. However, sometimes the welded pipe is more expensive due to market pressure.

4. Performance and use

Seamless steel pipe has better pressure-bearing capacity and higher strength than ERW welded steel pipe. Therefore, it is widely used in high-pressure equipment, heat, boiler industry. -general welded steel pipe is the weak point of the weld, good or bad quality affects the overall performance.

5. Corrosion

Seamless steel pipe usually does not show any signs of corrosion unless it is in a highly corrosive environment, while the welded area in a welded pipe is more susceptible to corrosive attack.

6. Wall thickness

Small thin-walled tubes are best produced by welding. Large thick-walled tubes are best produced using seamless methods.

7. Weld seams

The weld area is its weak point and the quality of the weld is a major factor in the overall performance. The presence of any seam on a welded tube is a weak point, but if the tube is seamless it tends to be solid and to overcome various industrial forces and pressures during operation.

8. Welding performance

There are some differences in the chemical composition of welded and seamless steel pipes in general. The production of seamless steel components is just asm the basic requirement.

9. Forming process

Seamless steel pipe and welded pipe is mainly different forming process. Seamless steel pipe can be formed in the rolling process in one go. Welded steel pipes are manufactured from steel strips or plates, by bending and different welding processes.

Please contact us to get the steel pipes you want, and we offer professional suggestions.